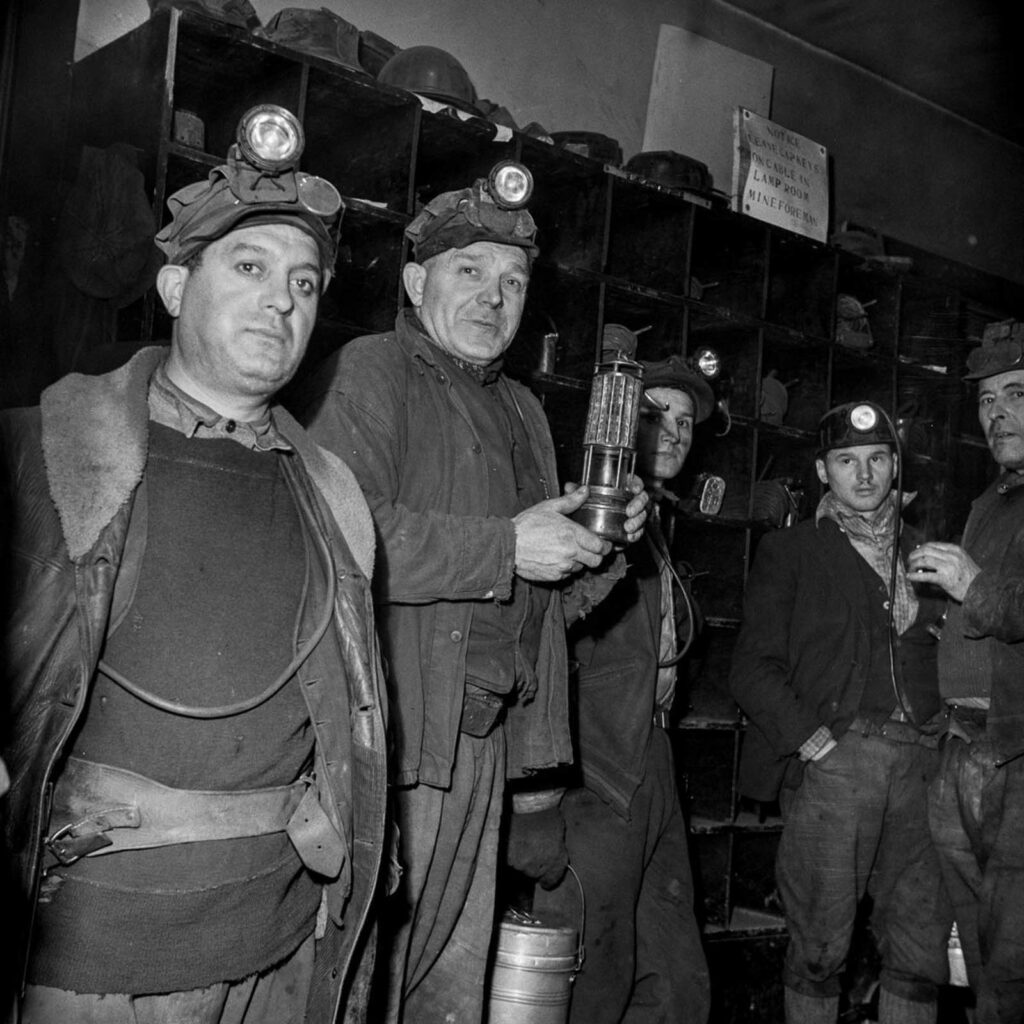

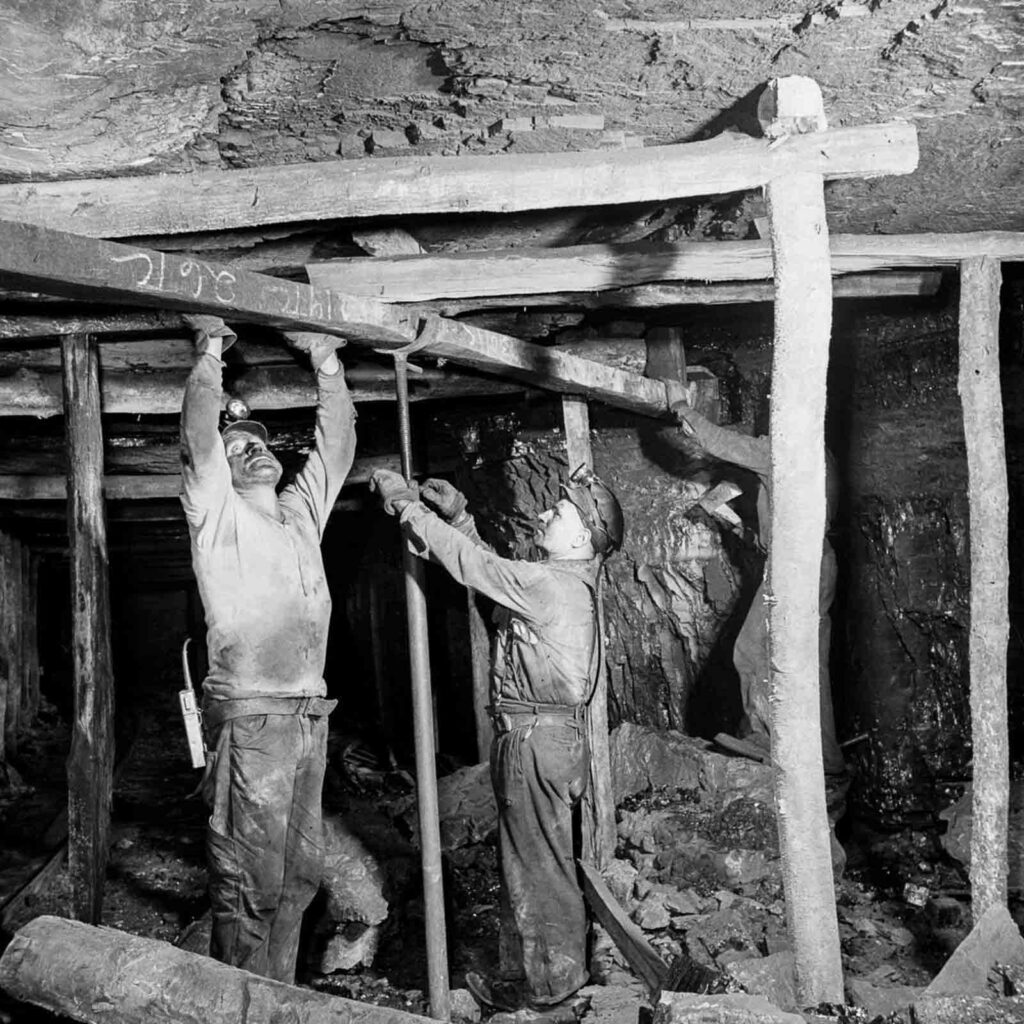

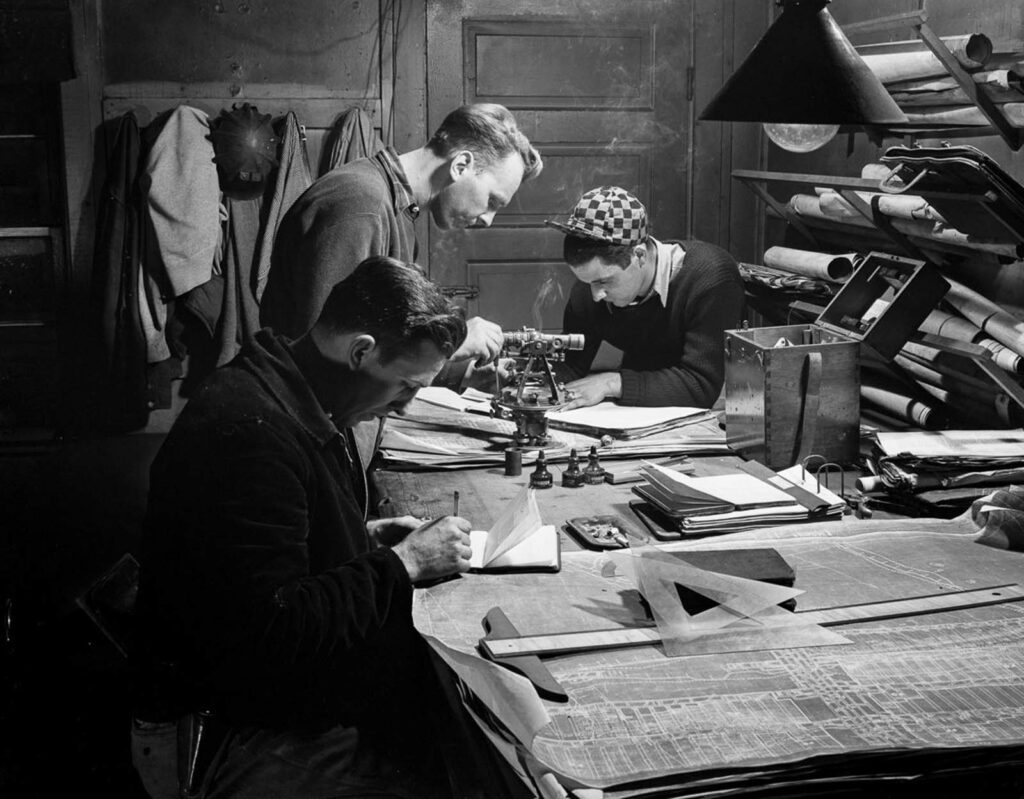

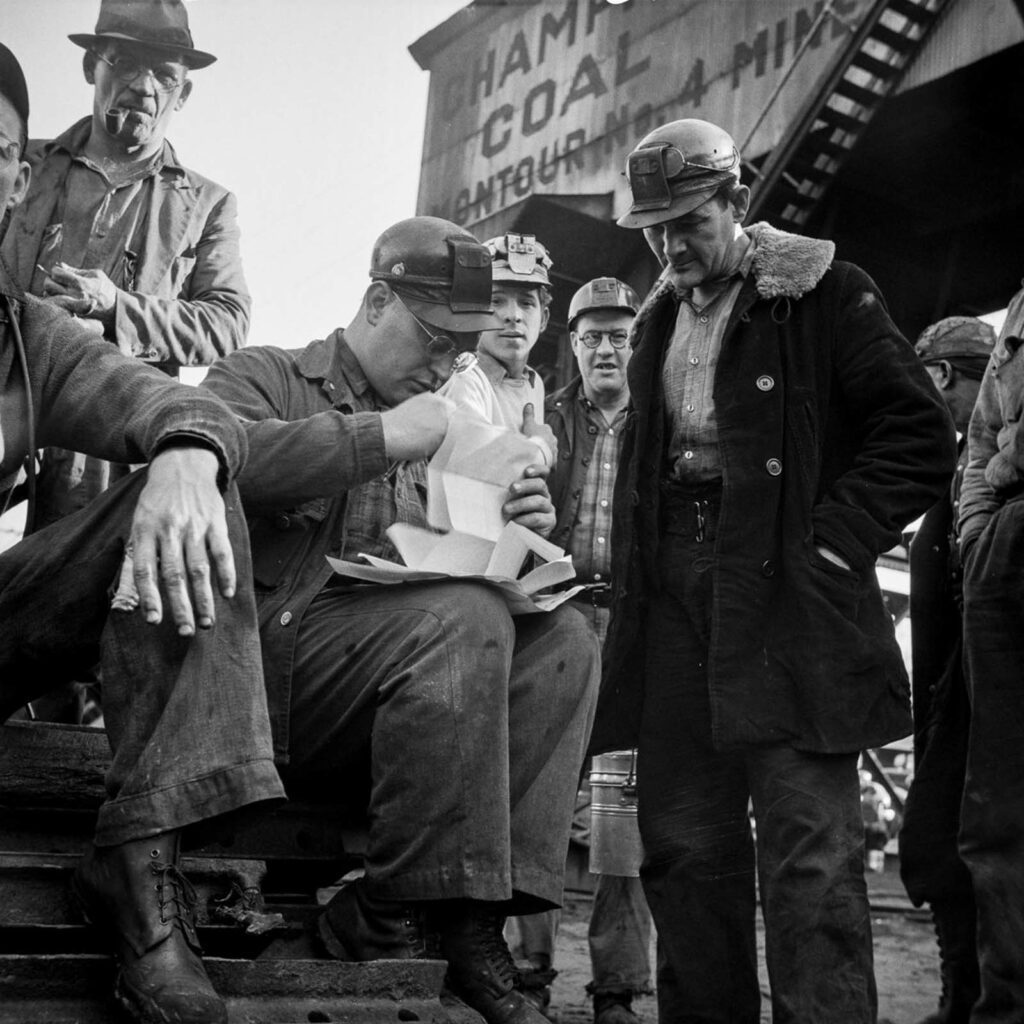

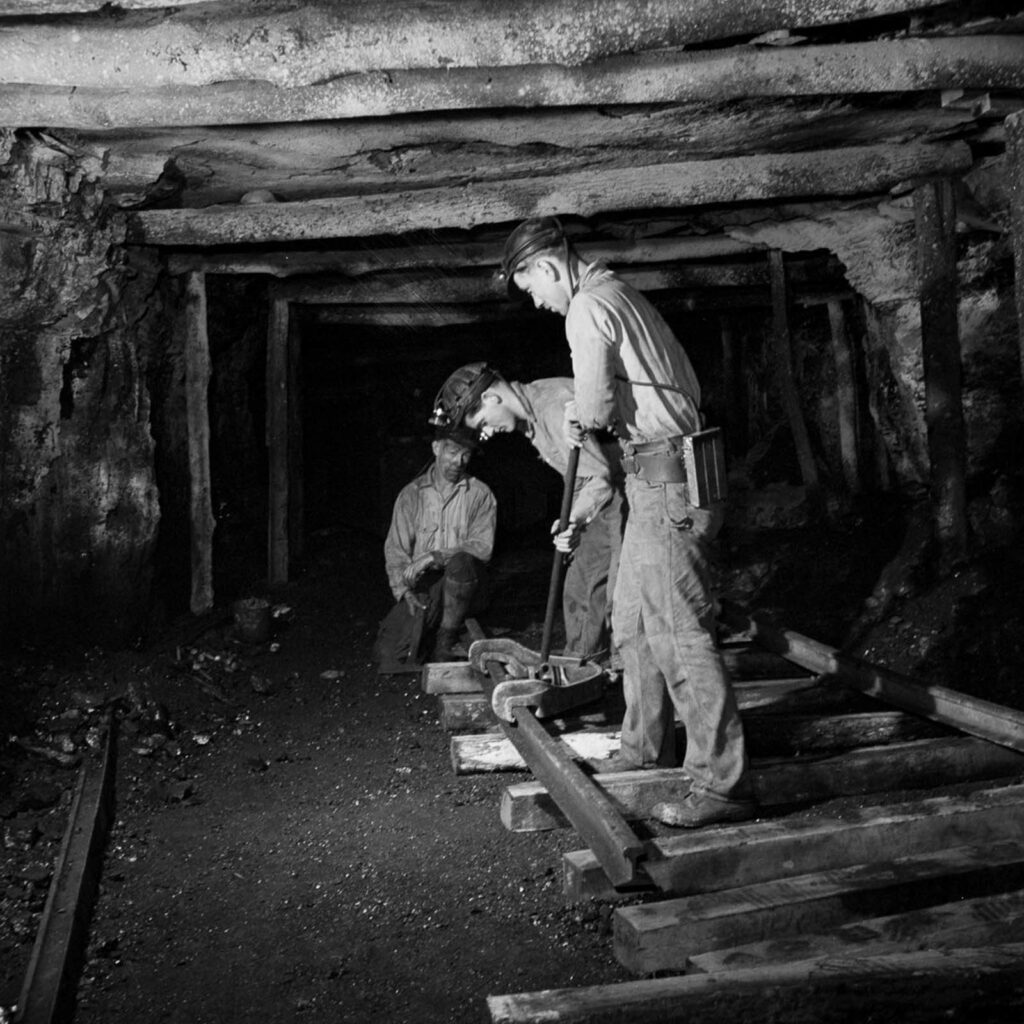

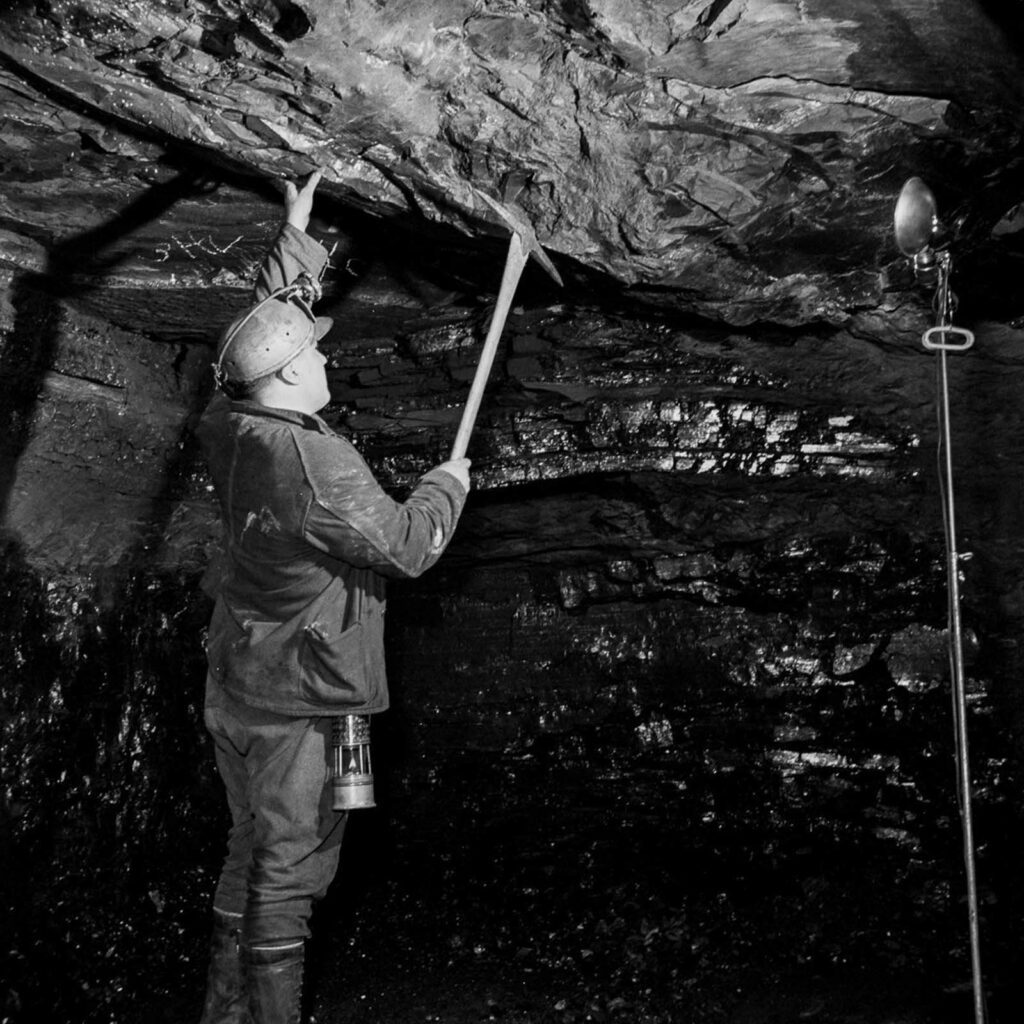

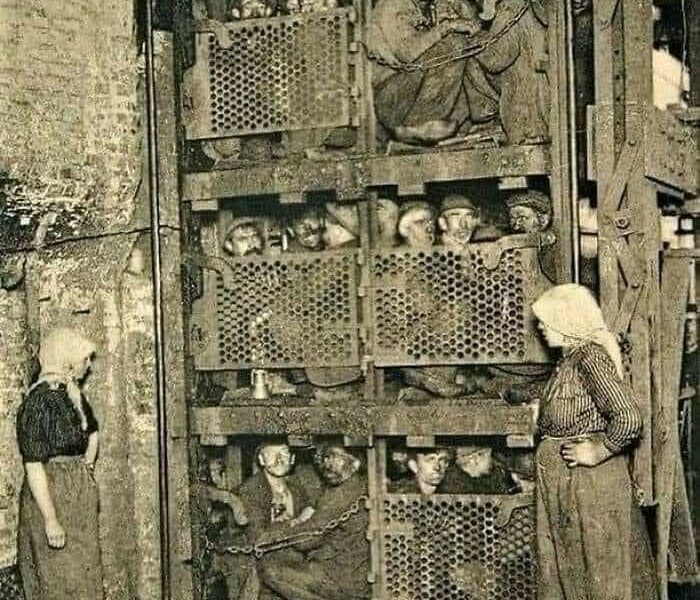

The long history of coal mining in Pennsylvania John Collier, a photographer for the Office of War Information, took the photographs in this article. They show the hard lives of miners working in the Pittsburgh Coal Company’s Montour No. 4 Mine.

Collier wrote about the miners’ lives underground, as they laid tracks, set up apparatus, drilled, and blasted with dynamite while being careful not to let anything fall.

Vesta Montour #4 My mine used to be the biggest bituminous coal mine in the world. The mine operated about 1903 and closed in 1957. It reopened for a short time in 1960 and then closed for good in 1984.

Dating back to the late 1700s and grew quickly between 1870 and 1930.

At “Coal Hill” (Mount Washington), just across the Monongahela River from Pittsburgh, Pennsylvania, bituminous coal was first mined.

The coal came from drift mines in the Pittsburgh coal seam, which is visible along the slope. It was then transported by canoe to the nearby military base.

By 1830, Pittsburgh used more than 400 tonnes of bituminous coal every day for homes and light industry.

The anthracite coalfields in eastern Pennsylvania had grown to the point where “hard coal” had taken over the eastern markets.

As a result, the production of bituminous coal in western Pennsylvania increased mainly because the population grew, rail and river transportation facilities were built and improved to the west, and the steel industry started to thrive.

In the later part of the 1800s, the railway and shipbuilding industries grew so quickly that they needed a lot of steel. This had an even bigger effect on bituminous coal production in western Pennsylvania.

The “room-and-pillar” approach was utilised in the early mines. This method involves mining material across a horizontal plane, which creates horizontal arrays of rooms and pillars.

People had to cut the coal at the working face, and horses and waggons had to carry it out of the mine.

As shown in these photographs, many room-and-pillar mines now use mechanised continuous mining machinery to cut the coal and a network of conveyors to move the coal from the working face to the surface.

(Photo credit: Library of Congress).

No Comments